Surface mirror

When it comes to building optical devices as well as instruments, surface mirrors (front surface mirrors) are the first choice. We offer a wide range of high quality optical mirrors for various applications.

Very low absorption values

Maximum reflection

Own development department

Surface mirror

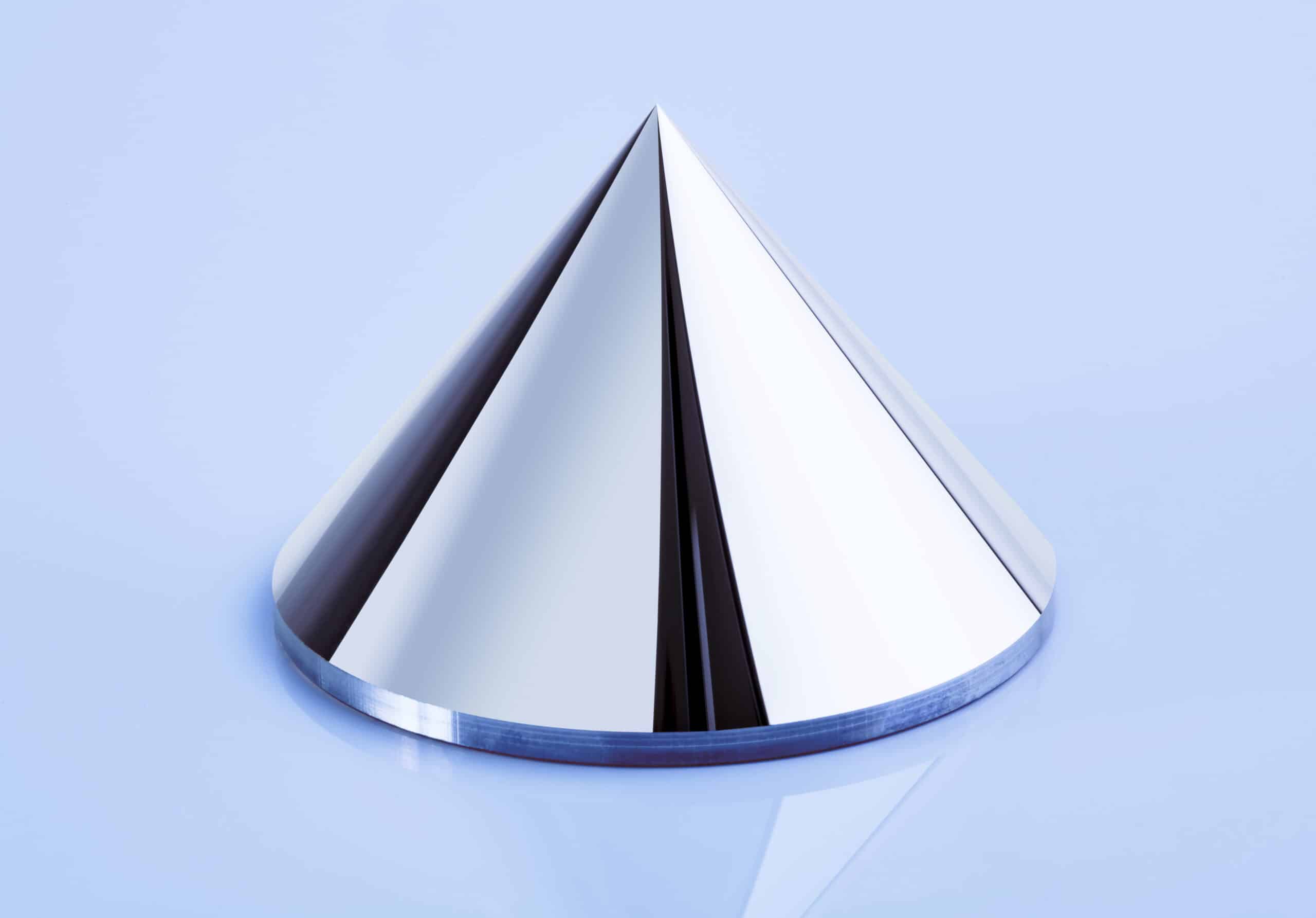

Surface mirrors are also called front surface mirrors and are optimized for maximum reflection in terms of coating. For this reason, we use only materials that are carefully machined and precisely polished in the production of surface mirrors. Surface mirrors are available in different variants. Choose between plano mirrors and spherical concave mirrors to find the most suitable products.

The following materials are used for the production of surface mirrors:

- Metals

- Semiconductors

- Optical glasses

What are the advantages of surface mirrors from Pleiger Laseroptik?

- Metallic or dielectric coating

- Optimal for optical device and instrument manufacturing

- Perfect for laser applications and laser systems

- Available in many variants according to customer specifications

- Available as flat or curved version

- No chromatic aberrations

At Pleiger Laseroptik, you can choose between a wide variety of surface mirrors that are excellently suited for the production of optical devices, instruments as well as laser applications and systems. If you need surface mirrors for broadband applications, the metallic coatings are perfectly adequate. Metallic coatings also provide adequate reflection for low power laser systems. However, if a particularly high reflection is required, the so-called “enhanced coating” is used. Here, the reflection is optimized by applying dielectric layers. In this case, however, only a small spectral range can be enhanced.

An optimization of the dielectric layers and the optics to one wavelength takes place. Metal mirrors are front surface mirrors that are characterized by high broadband reflection and are therefore ideally suited for optical and technical systems as well as low power laser systems. Pleiger Laseroptik has specialized in the production of high-quality surface mirrors for more than 20 years and offers these optical components as plano mirrors, spherical mirrors (concave or convex), parabolic mirrors as well as toroidal and cylindrical optics.

Do you need

optics ready for immediate use?

Here you will find our overview of optical mirrors.

Glass mirror

Glass mirrors often have a problem with multiple reflections. However, since in a front surface mirror the light does not penetrate the glass at all, but is reflected directly from the surface of the mirror, this problem does not occur with surface mirrors.

It should be noted, however, that the mirror coating is highly sensitive to chemical and mechanical influences. With a high-quality coating, the resistance of the optical mirrors is increased.

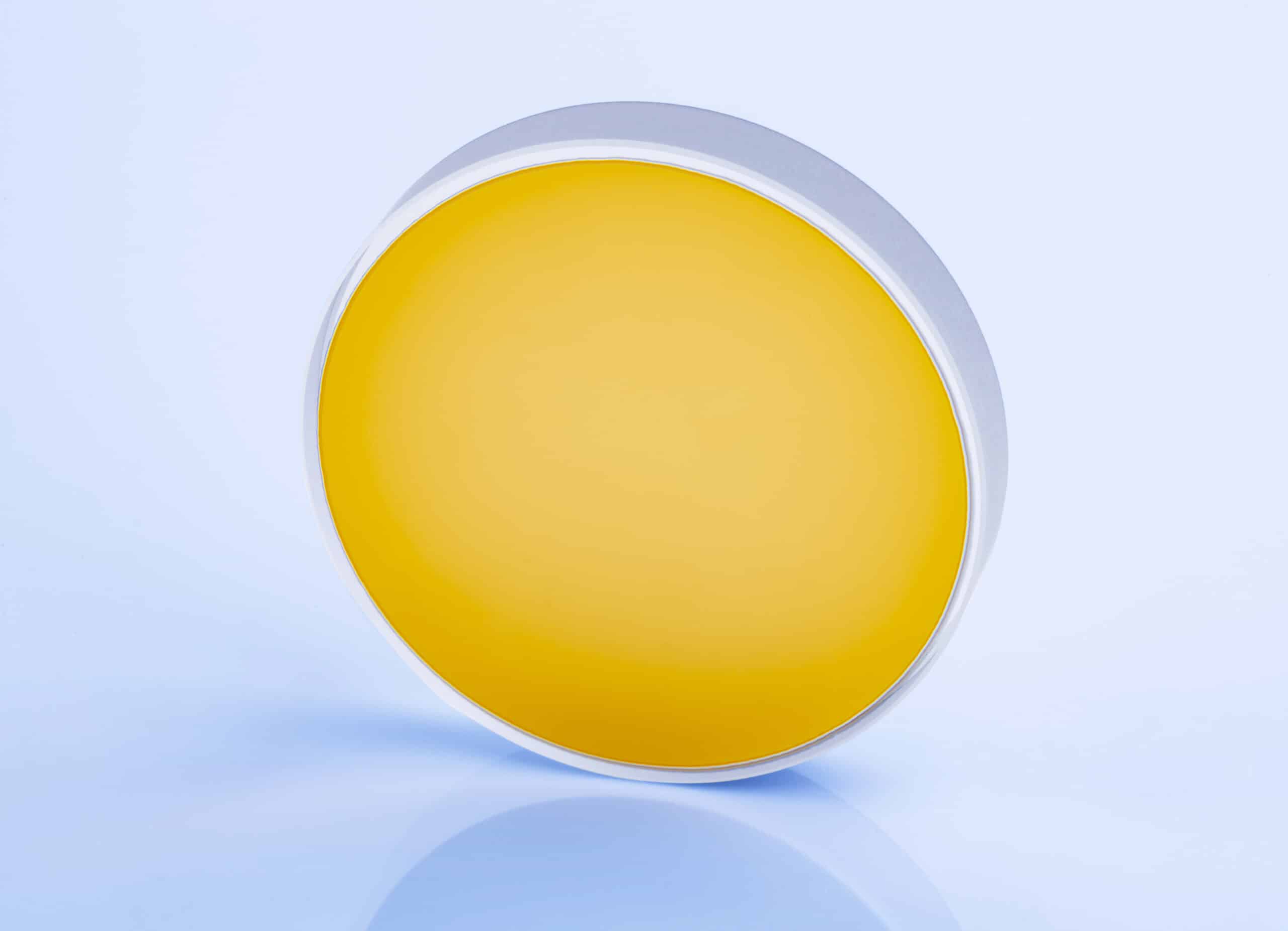

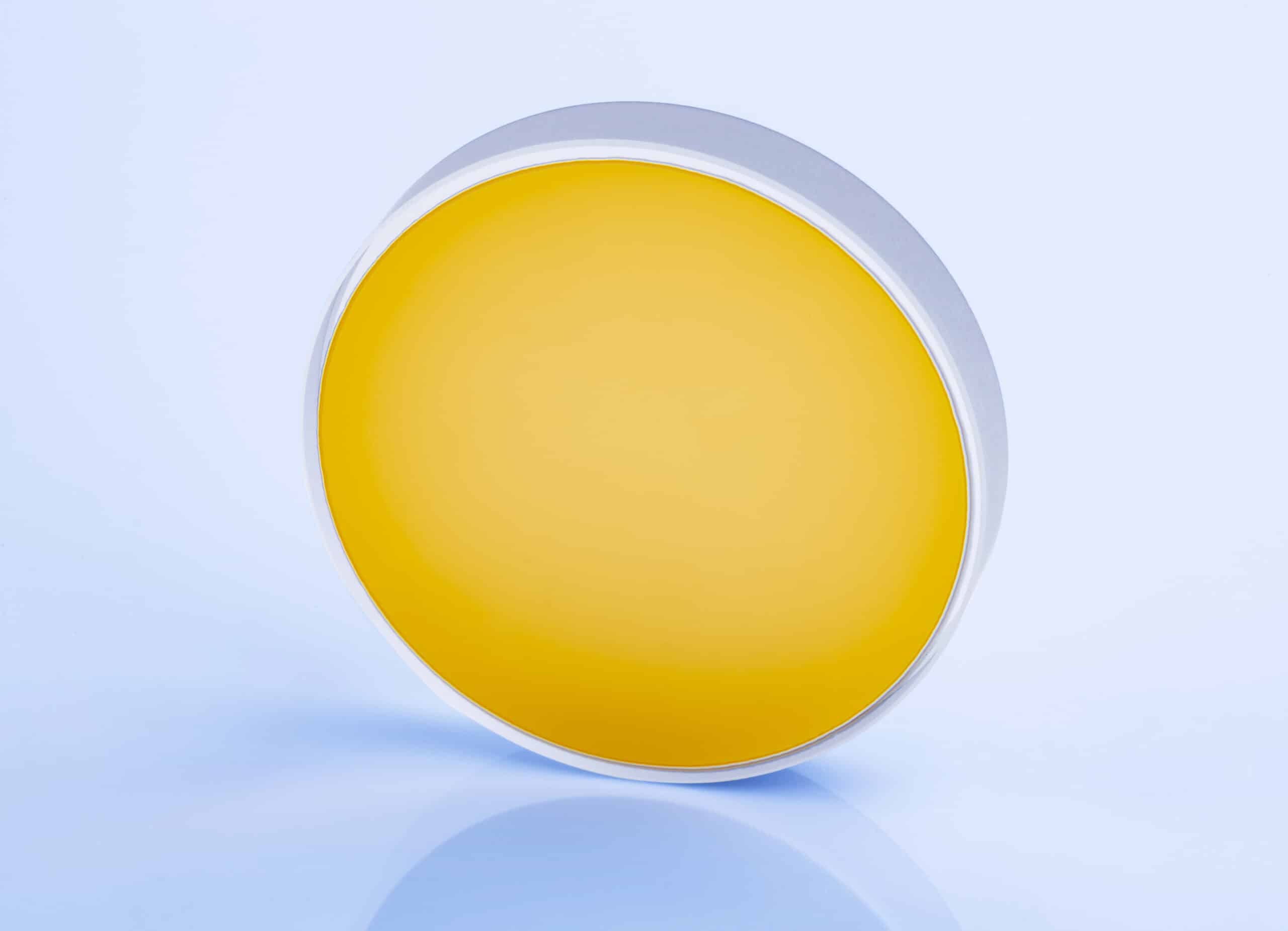

Gold mirror

Gold mirrors are preferably used in the infrared spectral range. We recommend using these surface mirrors from a wavelength of 700 nanometers. The precious metal gold is characterized by not tarnishing. For this reason, gold mirrors can also be used without a protective coating. However, to allow occasional cleaning, it is recommended to protect the relatively soft material gold by applying a dielectric layer.

Gold mirrors are made of various materials:

- Quartz

- Silicon

- Copper

- Aluminum

- Other optical materials

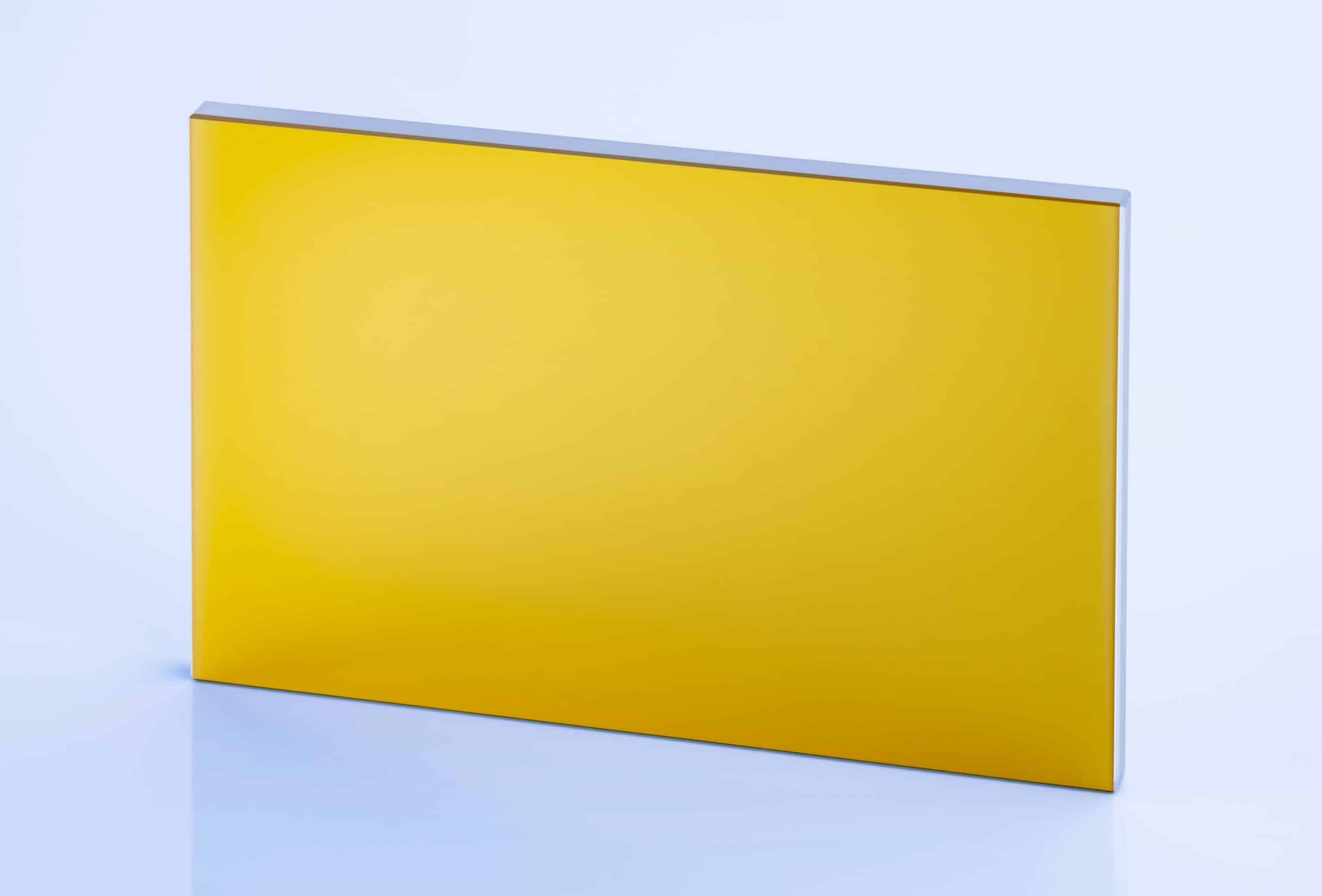

Silver mirror

Silver mirrors are preferably used in the visible to infrared spectral range. There, silver shows the highest reflection of all metals. However, since silver tarnishes easily and the reflection drops with time, we recommend always protecting these surface mirrors with a layer of oxide. This protective layer slows down the aging process, but cannot prevent it completely.

Silver mirrors, like gold mirrors, are made from a variety of materials:

- Quartz

- Silicon

- Copper

- Aluminum

- Other optical materials