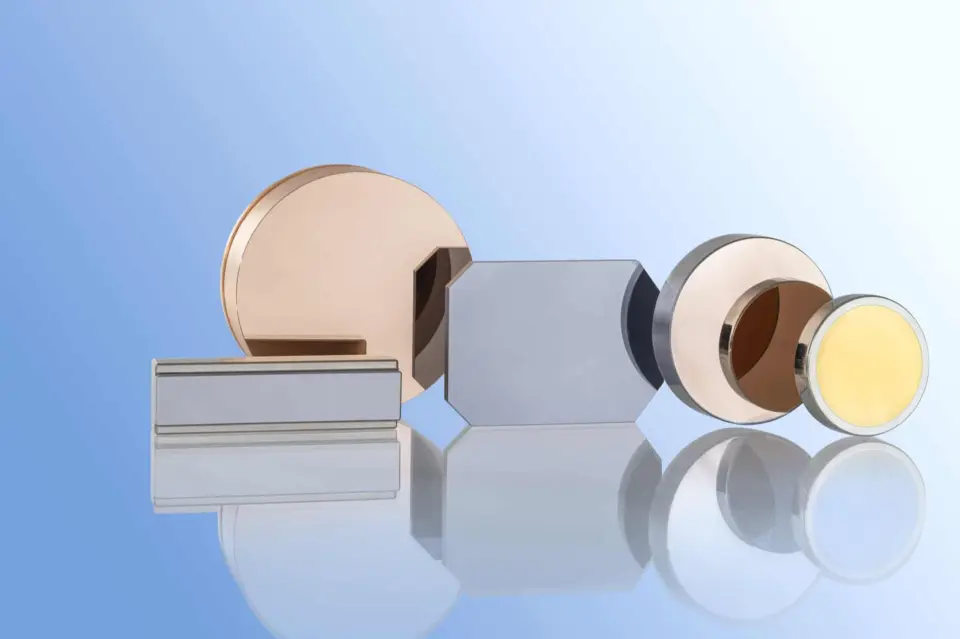

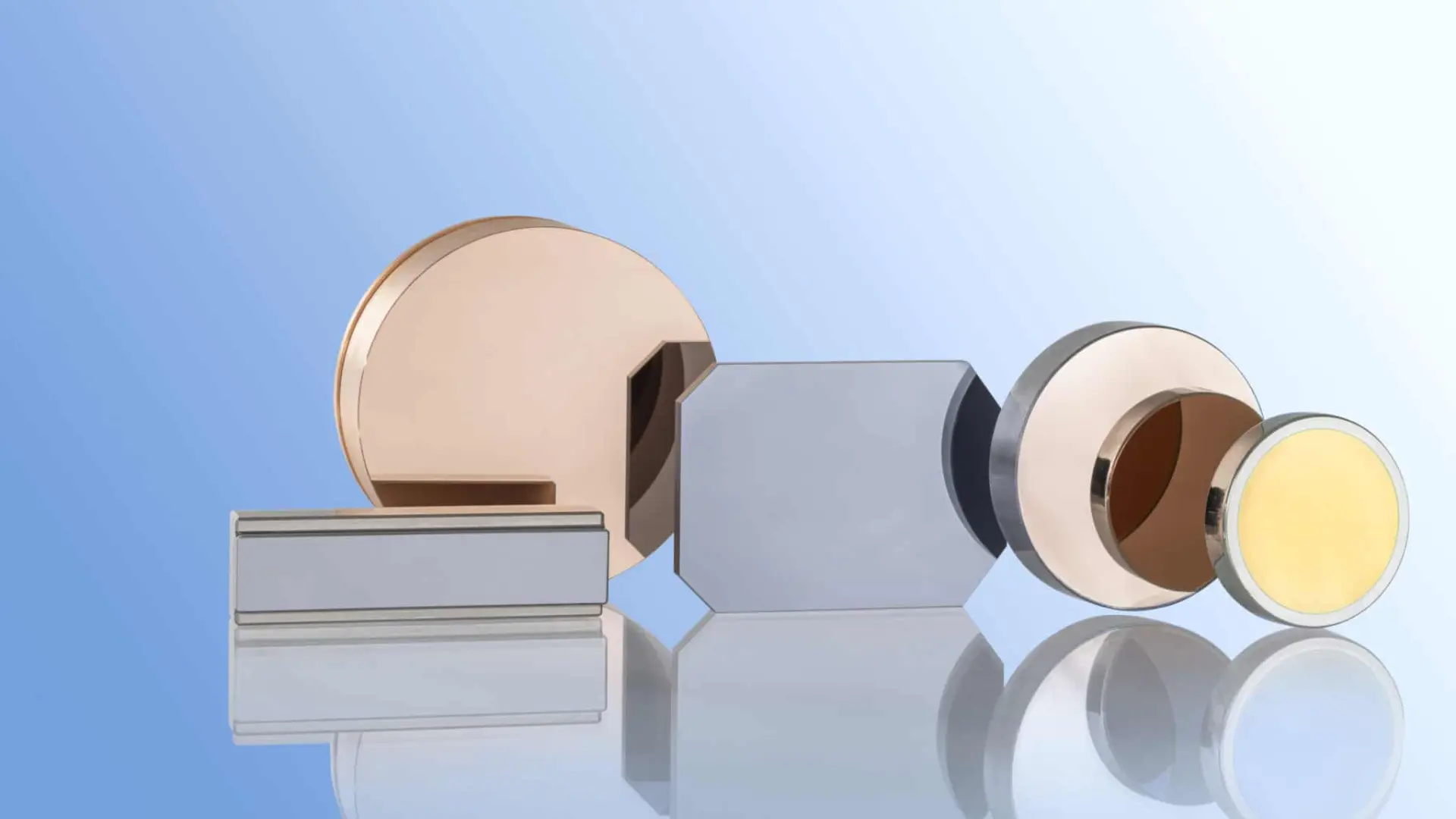

Laser optics

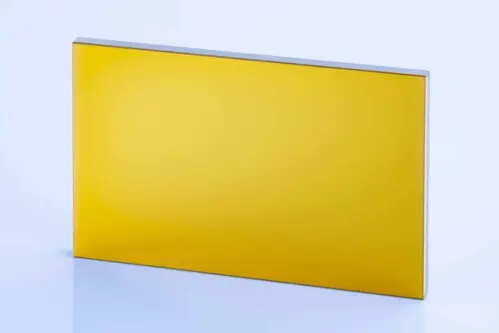

The coated laser optics are required in many optical industries. With the help of optical coatings, the reflectivity of surfaces can be controlled and specifically influenced for the area of application. In the field of laser optics, a distinction is made between metallic and dielectric coatings. The distinction is based on the coating material. In the case of metallic coatings, for example, aluminum or silver is used for the production of reflectors. Dielectric coatings are used to maximize reflection. The physical properties of the metals used determine the reflectivity.

Coating Service for Supplies

We apply high-quality metal coatings—such as gold, silver, aluminum, platinum, and rhodium—to supplied optical components.

Our coatings are designed for UV to IR applications, making them ideal for metrology, laser scanning, laser material processing, and broadband optical systems.

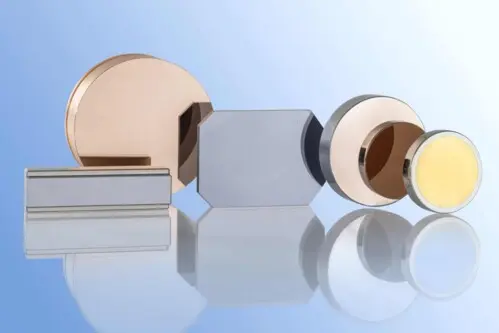

Metal Optical Coatings

Pleiger Laseroptik uses a variety of high-quality materials for coating

Innovative Laser Optics - The benefits at a glance

Absolute reliability

Outstanding quality

High level of expertise

Coating of metals, semiconductors and glasses

Production of ready-to-use optical components

Take advantage of our experience and expertise in the field of laser optics. We have been part of the Pleiger group of companies for more than 20 years and have coated well over a million optics during this time. We are not only a competent, but also a renowned partner for various companies in the optics industry and are characterized by a high level of innovation. Find out more about the manufacture of CO2, metal and state-of-the-art laser mirrors.