The design and manufacture of Pleiger Laseroptik’s resonator mirrors achieve the highest standards in every respect. Under the harsh conditions in CO2 laser resonators, they ensure constant laser output and are ideally suited for specific applications in the industrial environment for processing materials such as metal, dielectrics or organic materials.

CO2 lasers have become indispensable as powerful tools in the field of materials processing. Along with solid-state lasers, they are among the most effective types of lasers used in the industrial environment in the processing of metals or, for example, for the thermal ablation of plastics, but they are also ideal for marking organic materials or substances such as wood, cardboard or leather. Such gas lasers are not only suitable for surface processing, marking and labeling workpieces, but also guarantee excellent results when welding or cutting. Because of their power density and high beam quality, CO2 lasers are among the most powerful laser types for industrial applications.

In carbon dioxide lasers, CO2 generates the laser beam. Excitation is first achieved by an RF glow discharge of N2 molecules. In the second step, these emit their energy through collisions with CO2 molecules. If a photon hits the excited CO2 molecule, the CO2 can release its energy by emitting another photon. The two photons are coherent (in phase).

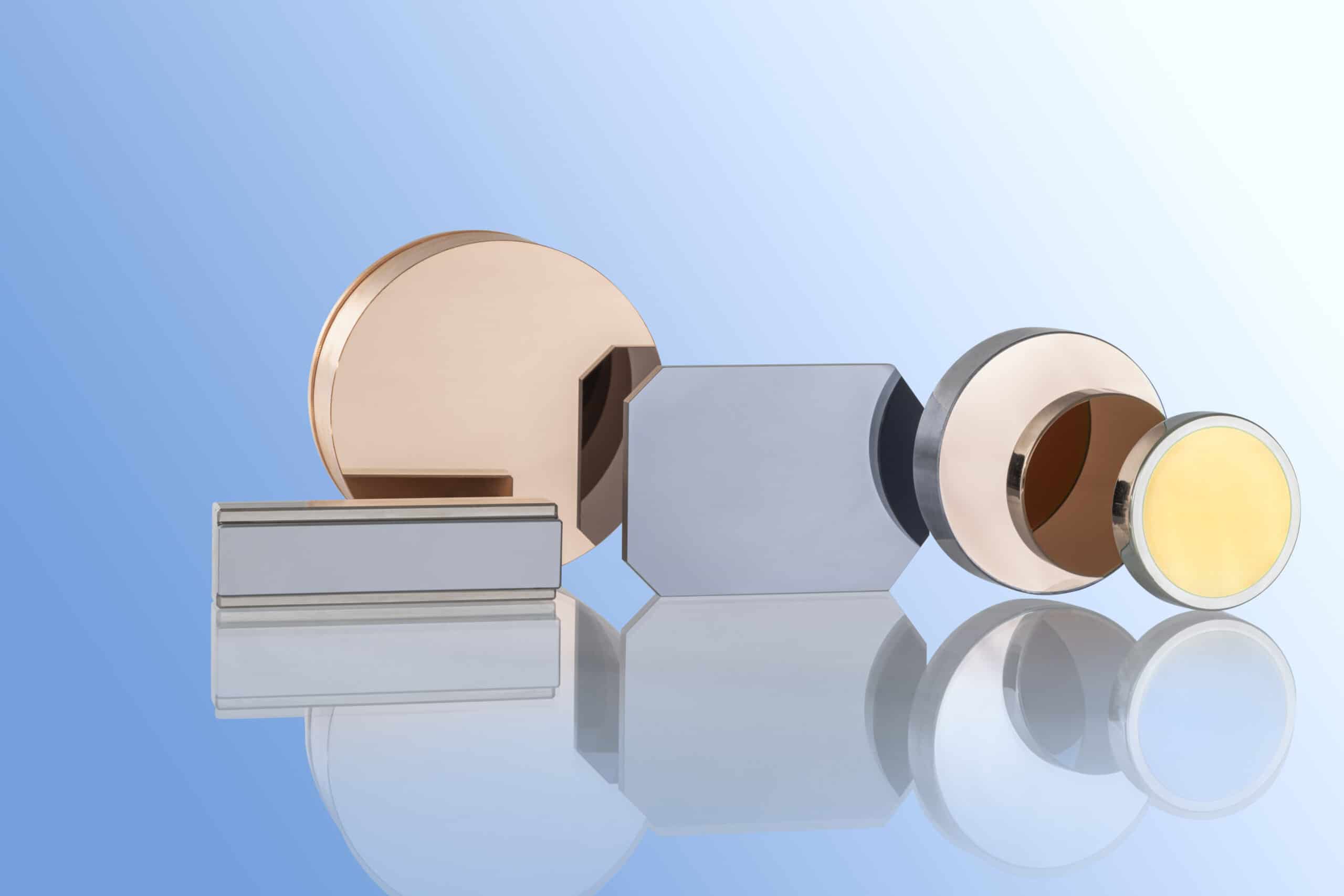

Pleiger resonator mirrors (plane mirrors or spheres) are precision elements in such CO2 laser resonators or laser systems which are decisive for their performance: The emitted monochromatic photons show an extraordinarily high coherence. Depending on the application and the physically required property (reflectivity), the resonator mirrors are metallic or dielectric coated.

In addition to their use in resonators, CO2 laser mirrors from Pleiger also serve as deflection units and are also used for beam shaping. Resonator mirrors from Pleiger are precision-manufactured in our own development department according to the requirements profile or customer-specific specifications. The high-power mirrors for CO2 resonators meet the highest standards with regard to reflectivity (R > 99.8 %) and stability under the demanding conditions in the specifically desired areas of application. The use of CO2 lasers enables a uniform processing of materials and impresses with a superior efficiency compared to other processes.

Contact us here if you would like more information about our products in the field of laser optics.

Pleiger Laseroptik – your partner for high-quality optical components and coatings for more than 20 years.